Annual Oscillot System Maintenance: Seasonal Care Guide for Australian Climates

Annual Oscillot System Maintenance: Seasonal Care Guide for Australian Climates

Protecting Your Investment Through Year-Round Maintenance

Australia's diverse climates—from tropical humidity in the north to temperate zones in the south—create unique maintenance requirements for cat containment systems. Oscillot's passive mechanical design requires minimal upkeep, but understanding seasonal maintenance protocols ensures your system performs reliably for decades. This comprehensive guide covers seasonal maintenance strategies tailored to Australian weather patterns and environmental conditions.

Unlike complex pet fencing systems requiring professional servicing, Oscillot maintenance is straightforward DIY work requiring basic tools and 30–60 minutes per season. The key is consistency: regular maintenance prevents minor issues from becoming major problems and extends component lifespan indefinitely.

Spring Maintenance (September–October): Post-Winter System Check

After Australia's cooler winter months, spring is the ideal time for comprehensive system inspection and component verification.

Spring Maintenance Checklist:

- Visual inspection of all posts: Check for any visible cracks, brittleness, or discoloration indicating cold-weather damage

- Bearing rotation test: Manually rotate each paddle set through full range of motion; should operate smoothly without binding

- Bracket fastening verification: Tighten all bolts and fasteners (check for corrosion from winter moisture)

- Post cap condition: Verify caps are seated properly and haven't shifted during winter weather

- Ground level assessment: Check that soil hasn't settled, affecting bracket alignment

- Debris removal: Clear leaves, twigs, and winter debris from bearing assemblies

- Photographic documentation: Take wide-angle photos of complete system for warranty records

Spring Maintenance Deep Dive:

Bearing Rotation Testing: This is the most critical spring task. Manually lift and rotate each paddle set through its complete rotation range (paddle should move freely from horizontal to vertical and back). If any resistance appears, clean bearing assembly thoroughly before concluding maintenance. Oscillot bearings rarely require lubrication—any stiffness typically indicates debris accumulation rather than bearing failure.

Fastener Inspection: Australian spring weather can bring moisture and temperature fluctuation. Use an adjustable wrench to tighten each bolt on bracket assemblies—a quarter-turn is usually sufficient. Don't over-tighten, which can crack plastic components. If bolts show white corrosion (aluminum oxide), wipe clean with a dry cloth.

Summer Maintenance (November–February): Heat and Humidity Management

Australia's hot, humid summers present unique challenges for outdoor equipment. High temperatures and moisture create conditions favoring oxidation and plastic degradation.

Summer Maintenance Priorities:

- Monthly bearing rotation tests: Heat acceleration makes monthly checks valuable (rather than seasonal checks)

- Debris management: Weekly removal of leaves, pollen, and organic matter from bearing assemblies

- UV protection inspection: Verify plastic components haven't become brittle from extended UV exposure

- Corrosion monitoring: Check aluminum components for white oxidation indicating salt/humidity exposure

- Cat activity observation: Increased outdoor time means increased paddle interaction—monitor for wear patterns

Managing Australian Heat Effects:

Plastic Component Flexibility: Oscillot plastic paddles are engineered to remain flexible across Australian temperature extremes (from 45°C summer peaks to 5°C winter lows). However, extended direct sunlight can cause surface brittleness. If paddles feel stiff or brittle when tested, increase humidity by misting with water—flexibility typically returns within hours. This is normal weathering, not product failure.

Bearing Lubrication in Summer Heat: Oscillot bearings are designed for zero-maintenance operation. However, in extremely hot climates (40°C+), bearings may benefit from lightweight silicone spray once annually. This is optional maintenance but can extend bearing life in extreme conditions. Apply sparingly and wipe excess.

Autumn Maintenance (March–May): Pre-Winter Preparation

As Australia transitions to cooler months, autumn maintenance prepares your system for winter weather variation and establishes baseline conditions for spring assessment.

Autumn Maintenance Checklist:

- Deep bearing cleaning: Remove all accumulated debris using small brushes and compressed air

- Full fastener inspection: Check every bolt, nut, and fastener for tightness and corrosion

- Bracket alignment verification: Confirm brackets are perpendicular to fence (settlement or fence movement can misalign systems)

- Post cap seating: Ensure caps are fully seated and won't shift during winter weather

- Weatherproofing inspection: Check for any gaps where water might accumulate in bearing assemblies

- Structural integrity check: Visually inspect entire fence line for any movement or shifting

Pre-Winter System Hardening:

Australia's autumn rains can introduce moisture into bearing assemblies. Before winter, verify drainage around all bearing assemblies. If water accumulates, tilt brackets slightly to improve drainage or add small drain holes (consult Oscillot support for guidance). This prevents freeze-thaw cycles from damaging bearings in southern Australian regions.

Winter Maintenance (June–August): Cold Weather System Care

Australian winters are mild compared to northern hemispheres, but regional variations from Tasmania's cool climate to minimal winter conditions in northern Australia require location-specific maintenance.

Winter Maintenance Priorities (Temperate Regions):

- Reduced frequency checks: Winter inactivity reduces cat usage; maintenance can be less frequent than summer

- Moisture management: Ensure no standing water in bearing assemblies (critical in Tasmania and southern Victoria)

- Fastener inspection: Cool temperatures can cause metal contraction; retighten bolts monthly

- Plastic flexibility monitoring: Cold can make plastic slightly brittle; test paddle flexibility monthly

- Debris clearing: Winter leaves and organic matter can trap moisture; clear weekly

Winter Maintenance for Tropical Regions:

Northern Australia experiences tropical wet seasons with heavy rainfall and humidity rather than cold temperatures. Maintenance priorities shift to moisture management: monthly bearing inspections become critical, debris removal increases to twice-weekly (tropical vegetation sheds heavily), and moisture-reducing measures (light silicone spray on bearings) become more valuable. The same maintenance procedures apply—just with increased frequency due to environmental challenges.

Emergency Maintenance: Addressing Seasonal Issues

Issue: Paddles Stiff in Cold Weather

Cause: Plastic naturally stiffens in cold. Solution: Mist with warm water; flexibility returns within hours. This is normal and not a defect.

Issue: Post Caps Shifting or Loose

Cause: Thermal expansion/contraction causes movement. Solution: Reseat caps and verify post-to-bracket fastening is tight. Consider adding small retaining clip if chronic issue (available from Oscillot spare parts: $8.95 AUD).

Issue: Bearing Assembly Won't Rotate Smoothly

Cause: 95% of cases are debris accumulation. Solution: Clean thoroughly with compressed air and small brush. If stiffness persists, contact Oscillot support (bearing replacement: $32–$42 AUD).

Issue: Visible Corrosion on Aluminum Components

Cause: Salt spray or humidity exposure creating white aluminum oxide. Solution: Wipe with dry cloth; this is cosmetic weathering, not structural damage. Severe corrosion (structural thinning) is rare and covered by warranty.

Replacement Parts and Maintenance Costs

Oscillot's modular design means occasional component replacement is simple DIY work requiring no professional installation:

Common Replacement Parts (Australian Pricing):

- Post Kit Cap: $5.90 AUD (simple snap-on replacement)

- Dual Knuckle Post Kit: $25.59 AUD (replacement bearing assembly)

- Bracket (single): $4.80 AUD (quick-swap component)

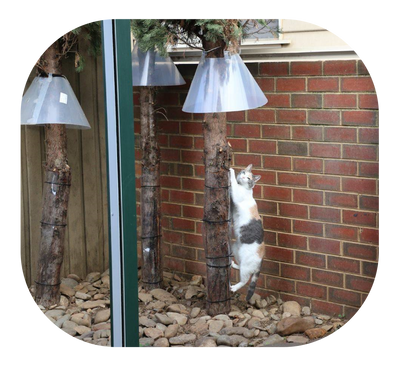

- Cat Tree Guard: $41.59 AUD (tree/pole protection)

- Axle Pin (replacement set): $4.46 AUD (wear item after 5+ years)

- Cat Paddle Set (pair): $38.40 AUD (rarely needed)

Five-Year Maintenance Cost Estimate: $50–$150 AUD in replacement components (if needed). Most Australian installations require zero replacement parts during this period.

Recommended Maintenance Schedule Summary

| Season | Frequency | Primary Tasks | Time Required |

|---|---|---|---|

| Spring | Once (September) | Full inspection, bearing test, fastener check | 45–60 min |

| Summer | Monthly | Bearing rotation, debris removal | 20–30 min |

| Autumn | Once (April) | Deep clean, weatherproofing check | 40–50 min |

| Winter | Monthly | Moisture check, fastener inspection | 15–20 min |

Professional Maintenance Services (Optional)

While Oscillot maintenance is designed as straightforward DIY work, some Australian property owners prefer professional support:

- Annual maintenance service: Professional technician performs all seasonal checks ($150–$250 AUD)

- Quarterly deep-clean service: Bearing assembly cleaning and component verification ($80–$120 AUD per visit)

- Post-installation documentation: Professional photographer documents installation baseline ($75–$150 AUD, valuable for warranty claims)

Contact your local Oscillot installer to inquire about maintenance service availability in your region.

Warranty Impact of Maintenance Documentation

Maintaining detailed records of your seasonal maintenance significantly strengthens warranty claims and demonstrates responsible ownership:

- Date-stamped photographs from each seasonal maintenance session

- Written log of maintenance activities and any observations

- Records of any component replacements

- Notes on environmental conditions (salt spray exposure, extreme temperature events, etc.)

These records transform warranty claims from "It stopped working" to "System was professionally maintained and failure appears to be manufacturing defect"—a much stronger position.

Your System's Long-Term Performance

Oscillot systems installed in Australia continue functioning reliably for 20+ years with only basic seasonal maintenance. The investment in 2–3 hours per year in maintenance is minimal compared to the peace of mind and system longevity you receive.

Shop Replacement Parts & Accessories

Consistent seasonal maintenance is your guarantee that your Oscillot system performs flawlessly year after year, keeping your cats safe regardless of Australia's variable climate conditions.

Leave a comment